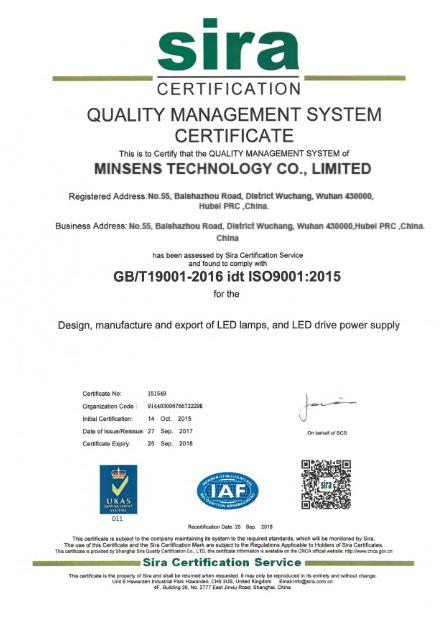

As an ISO 9001 listed company , MINSENS TECHNOLOGY CO., LIMITED is following strict rules to assure constantly high standards.

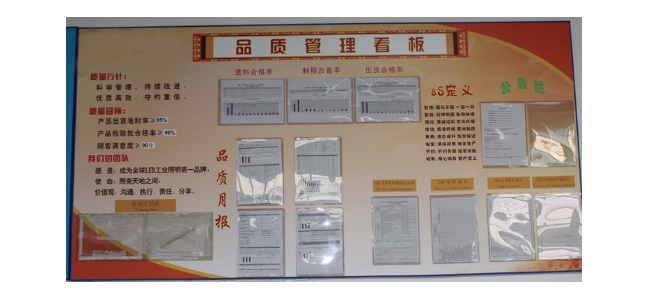

QUALITY GOAL:

1. On time delivery rate≥ 95%

2. Products passing rate per batch ≥ 98%

3. Customer satisfaction rate ≥ 90

During production, every semi-finished parts to be individually testing again before passing to next step of the production system; end of every assembly line all LED lamps goes through computerized switching, temperature variation, aging, universal bump tests for few hours. Starting from individual components test to final packing procedures each MINSENS products are inspected, tested and quality controlled in multiple levels.

MINSENS be sure to guarantee the product quality from raw material sourcing to production and after-sale service.

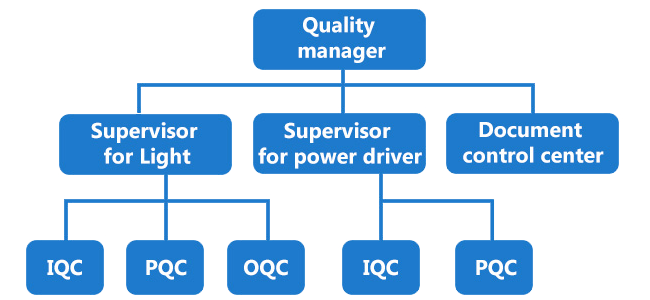

Quality Control Process under the following steps extremely strict;

1. IQC (raw material quality control)

2. IPQC (on production quality control)

3. FQC (finished product quality control)

4. OQC (delivery product quality control)

5. CQE (customer quality engineer)

Procedures/testing Details

A. Inspection to raw materials

B. Inspection in the process of production

C. Inspection to finished products

D. Aging test

E. Inspection before packing

Testing Details: QC manual, Aging, Internal Auditing Management Procedure, Ineligible Management Procedure, Recording Management Procedure, Rectification Measures Management Procedure, Prevention Measure Management Procedure, Customer Complaint Processing Procedure.

Equipment: LED light intensity distribution analyzer, YF1000 light-color-electricity synthetic analysis system, PMS-80 UV-visible-near infrared light spectroscopic analysis system, oscillograph, and digital/mechanical multimeter, salt spray tester, luminometer, and luminosity integrating sphere.

Pass the Quality Management System Certification

Based on “product quality is enterprise’s life” concept, MINSENS actively adopts the quality management system certification: in the year of 2010, we passed ISO quality management system certification-ISO9001:2008, our company has been improving and maintaining quality management system continued to operate effectively.

1. QC/Technical Support

We have more than 10 staff for in-house QC. There are integrated Training Programs for all the QC staff.

We strictly follow ISO 9001:2000 standards in the QC system.

pics need added

2. Number of QC Staff:

16 QC engineers

Every month, QC department will release monthly report to all the staffs and educate how to prevent the quality issue happening again.

Full quality control

1 Incoming material inspection

2 Sensitive material like LED chips and driver are stored in the constant temperature and humidity

3 Every LED PCB must be tested after assembled by SMT machine.

4 QC inspection during the production process.

5 Every light must be tested 4 times during the production.

6 100% lights must be tested before packing.

7 QC stamp on the qualified products and allow shipment.

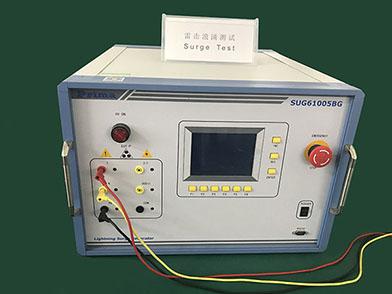

Quality assurance instrument

1 IP grade Tester

2 Salt spray Tester

3 IES-Machine

4 Integrated Spheres

5 Drop Tester

6 Constant Temperature & Humidity Test

7 EMI Test

8 Programmable AC Power Source

9 LCR Meter

10 LCR Digital Electric Bridge

11 Surge Test

12 Hi-Pot Test